Introduction

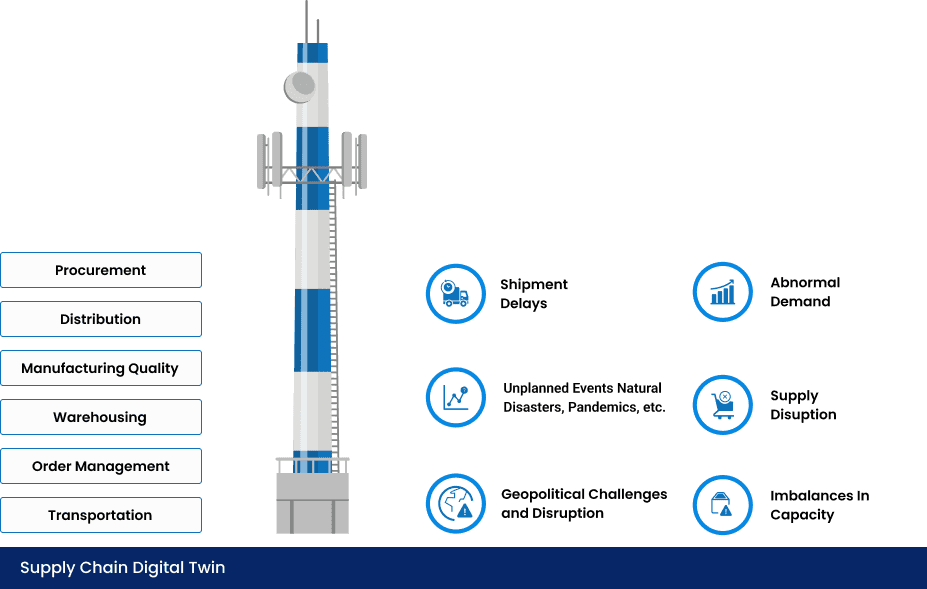

In today’s challenging environment of supply chain disruptions, supply chain needs to rapidly sense and respond to internal external disruptions. Supply Chain disruptions have become the new normal that includes rising costs, acute shortage of materials, shipment delays, shortages, capacity imbalances, natural disasters to name a few.

These disruptions further fuel inflation. The ability to deal with the supply chain disruptions is hampered by internal disruptions including siloed systems, inconsistent processes, and inconsistent data.

Supply chains need to Rapidly Sense and Respond to Internal and External Disruption

External Disruption

Internal Disruption

A control tower can help companies navigate through these complex supply change disruptions. Further a Control Tower used in conjunction with a Digital Twin can significantly help a company be resilient.

What is a Control Tower?

Control towers in supply chain management refer to digital platforms that provide visibility and control over all aspects of a company’s supply chain operations. These control towers use data analytics and other technologies to provide real-time insights into supply chain performance, allowing companies to make more informed decisions and improve the efficiency and effectiveness of their supply chain operations.

This can help companies reduce costs, increase customer satisfaction, and gain a competitive advantage in the market.

Digital Twin and Control Tower Connection

The digital twin is a virtual representation of a company’s supply chain operations. With a digital twin companies can essentially simulate supply chain’s performance and analyse various inflation and volatility scenarios.

Digital twins and control towers can be connected in several ways to improve supply chain management.

By connecting a digital twin to a control tower, companies can use the real-time data and insights provided by the control tower to update and improve the accuracy of the digital twin. This can help companies gain a more detailed and accurate understanding of their supply chain operations, allowing them to identify potential bottlenecks and inefficiencies and make more informed decisions about how to optimize their operations. Additionally, the use of digital twins can also help companies evaluate and test different scenarios and strategies for their supply chain operations, allowing them to make more informed and strategic decisions about how to improve performance.

Types of Control Tower

Control towers have many use cases in Supply Chains. They are used in logistics, transportation, inventory management, manufacturing to name a few.

For Example

- Predicting customer shipment delays in order management

- Providing End-to-End visibility and real-time insights into supply chain

- Supply shortages leading to production delays and identifying parts are at risk in procurement

- N-Tier visibility and understanding your Tier 2 & Tier 3 suppliers in procurement

Control Tower business benefits

The following section further elaborates some business benefits of Control Tower

Reducing delivery time on customer orders

A control tower in supply chain management can help reduce delivery times by providing real-time visibility into the entire supply chain. This allows companies to identify bottlenecks and other inefficiencies in their operations and take action to address them.

For example, a control tower can help companies identify delays in the movement of goods, such as at a particular warehouse or along a specific transportation route. With this information, companies can take steps to address the issue and improve the flow of goods, ultimately reducing delivery times. Additionally, control towers can also help companies optimize their transportation routes and choose the most efficient carriers, further reducing delivery times.

End to end visibility

As the use of technology and data analytics continues to advance, control towers are likely to play an even more prominent role in supply chain management in the future. In particular, the growing adoption of the Internet of Things (IoT) and other advanced technologies will enable control towers to provide even more detailed and real-time insights into supply chain operations. This will allow companies to make more informed and strategic decisions about how to optimize their supply chain operations and further improve efficiency and effectiveness. Additionally, the increasing focus on sustainability and environmental issues is likely to drive the development of new technologies and solutions that will be integrated into control towers, allowing companies to monitor and manage their supply chain operations in a more sustainable and responsible manner.

Managing real time expectations

Yes, control towers can help companies meet quick time expectations by providing real-time visibility into the movement of goods and enabling companies to identify and address potential bottlenecks and delays in the supply chain. With this information, companies can make more informed decisions about routing and scheduling, which can help them optimize the movement of goods and reduce the time it takes to deliver products to customers. In addition, control towers can also provide insights into the performance of individual carriers and other partners in the supply chain, allowing companies to identify and work with the most efficient and reliable partners to further reduce delivery times and meet quick time expectations.

Better chain agility

Control towers in supply chain management can help provide a better and more flexible customer experience by enabling companies to gain real-time visibility into their supply chain operations and make more informed decisions about how to fulfil customer orders. With this information, companies can better anticipate and meet customer demand, and adjust their operations in response to changing customer needs. For example, control towers can provide insights into inventory levels and the availability of products, allowing companies to fulfil customer orders and reduce the risk of stockouts or delays quickly and accurately. Additionally, control towers can provide information about the performance of individual carriers and other partners in the supply chain, enabling companies to identify and work with the most efficient and reliable partners to ensure timely and accurate delivery of products to customers. Overall, the use of control towers can help companies provide a more flexible and responsive customer experience.

In Conclusion

Companies should expect increasing complexity in supply chain and the disruptions to continue.

Supply Chain Control towers & Digital twin in supply chain management is a critical capability that can provide a comprehensive view of all aspects of the supply chain, including planning, inventory levels, transportation, and warehousing.

By leveraging the power of data & modern technology advances, companies can have a complete picture of their supply chain operations and make more informed decisions with analytical driven insights about how to optimize their operations.